A universal joint, U joint, Cardan joint, Hardy-Spicer joint, or Hooke's joint is a joint in a rigid rod that allows the rod to 'bend' in any direction, and is commonly used in shafts that transmit rotary motion. It consists of a pair of hinges located close together, oriented at 90° to each other, connected by a cross shaft.

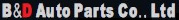

A universal joint, U joint, Cardan joint, Hardy-Spicer joint, or Hooke's joint is a joint in a rigid rod that allows the rod to 'bend' in any direction, and is commonly used in shafts that transmit rotary motion. It consists of a pair of hinges located close together, oriented at 90° to each other, connected by a cross shaft.Universal joint is an important component for vehicles. It provides a cost effective means to transmit power from the power source to the driven machine. Installation time is reduced as the need for critical alignment tolerances required by other types of couplings is eliminated. The telescopic feature eliminates the need for movement of machinery for installation or maintenance removal. The telescopic feature also allows motion during operation or no-load conditions.

2. How Does a Universal Joint Work?

In General

The job of a universal joint is to connect the driveshaft to the axle or output shaft in the transmission or transfer case. It allows the shaft to flex while it is spinning so that it won't bind. If quality universal joints are purchased and properly maintained, they will provide years of trouble free service. For four-wheel drive vehicles that see lots of dirt, water or mud, universal joints that are greasable are recommended to prevent premature failure and maintain good working order. Universal joints come in varying materials and levels of quality, and one should never get the cheapest model on the market just to save a few bucks. In the long run, this important component of the drive train will save you money and hassle if quality units are installed.

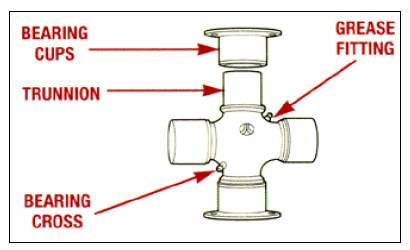

The Caps

A universal joint looks much like a plus sign with shiny round tips on all four ends. These round caps fit inside the axle shaft ends and onto the pinion yoke on the back of the axle housing. The caps are normally pressed in pretty good, and removal may require some finesse and force. A common way to remove them is to place a socket over the cap and pound it through to prevent damage of the connectors. The caps are sealed and greased inside to promote longevity and free movement. Over time, the seals on the caps may fail, especially with hard off-road use, allowing water and debris to penetrate to the inner workings of the universal joint. This will result in quick failure and is the reason they should be maintained and greased regularly.

Needle Bearings

Inside each of the four end caps are a series of rollers called needle bearings. Unlike ball bearings, needle bearings are long and round, much like the lead of a mechanical pencil. They are stacked around the entire inside of the cap and must be well lubricated in order for them to operate smoothly. For this reason, it is recommended you purchase the aforementioned greasable universal joints. Once the grease is forced in, it will not only replace the old grease but chase out contaminants as well, extending the life of the joint itself substantially. Be very careful when removing the end caps for universal joint installation, because these needle bearings tend to fall out and once they do, it is very difficult to get them lined up again.

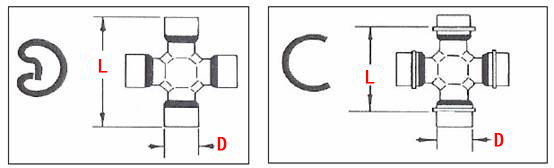

3. Measuring Universal Joints

Steps

Steps 1. remove bearing caps

2. remove excess grease from bottom of the bearing caps & trunnion

3. remove seals from bearing caps or trunnion –seals are removed,as they must be compressed for accurate measurements

4. reinstall bearing caps on trunnions

5. measure as follows:

-allow a tolerance of |

D: 0~-0.015mm

L: 0~-0.20mm

4. Installation and Maintenance

Lubrication

The following specification are given as a guide reference only,and do not apply where vehicle or machinery manufacturers have prescribed recommended lubricants and lubrication interval schedule. In the absence of above,the following guidelines can apply.

Method

Please ensure zerk(grease nipple) is thoroughly cheaned of old lubricant or foreign dirt particles.otherwise risk of contamination entering lubrication port may result.

Quantity Applied

Grease should be applied until excess grease is visible at each of the bearing cpas.Grease should be applied using manual grease gun, and not high-pressure lubrication equipment; otherwise risk of damaging bearing cap seals my occur.

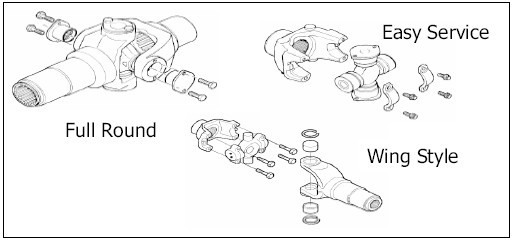

Methods of retaining Universal Joint Kits

English

English España

España  Français

Français  Россия

Россия Portugal

Portugal